“What can we do with our supply/value chains to accelerate the pace of change regarding sustainability?” asks SILC presenter Julia Redman, owner of Buyers Eye, who put forward some of her solutions.

With a fashion background that spans some 30 years – to include working in the buying departments of Arcadia Group, M&S, BHS, Woolworths, Debenhams and M&Co – Julia Redman, who now owns and manages retail buying and sourcing consultancy Buyers Eye, began her presentation to SILC attendees with some stark statistics about Scope 3 emissions.

“Scope 3 emissions are those that fall outside of our fashion stores and head offices, and are a major contributor to fashion’s carbon footprint,” she explained to SILC delegates.

Referencing a recent article in the Financial Times, she pointed out that it had highlighted that up to 80% of the fashion industry are in Scope 3, i.e. the value chains, and that many clothing brands, and subsequently suppliers, are not even attempting to measure their impact. In the same article, it was also reported that H&M estimates that Scope 3 emission make up 99.5% of its environmental impact.

Acknowledging that many fashion businesses are doing a great job of reducing their carbon emissions, she cited Superdry as an example of a fashion brand that has managed to cut its Scope 3 emissions by 96.3% by switching to renewable energy and reducing its air freight.

“There is obviously a huge amount that we can do,” she pointed out. “Essentially, we are talking about the value chains, and many, many brands who could do much, much more. Value used to be about product, quality and price. But there is so much more to that than there ever was in the past, and our sustainability and ethical and corporate responsibility/ESG, and speed to market, have been added into that value pot.”

Revealing a stark picture of the extent to which the fashion industry is contributing to global emissions, she revealed that fashion is the second most polluting industry, with the industry responsible for 10% of global carbon emissions; 20% of industrial water pollution and 92m tons of yearly solid waste dumped in landfills, with one truck of textiles wasted every second. (source: Marielle Pesant, Opitex).

“What these stats add up to is a huge impact on the environment. Over 92m tons of waste ends up in landfills, and over 60% of that is polyester, which is probably the worst contributor in the fashion industry as a fabric form, because it takes so long to bio-degrade. So not only do we need to think about the amount that’s going into landfill but of that landfill itself – what it is made of and how long it is going to take the environment to absorb that – if ever.”

She added the statistics followed on from the people element in fashion, highlighting that there are 430m people working in the industry – one in eight people in the workforce.

“Of those, many of them are in precarious and insecure work situations,” stressed Julia. “And over the past 18 months, with the impact of Covid, that situation has got worse. When we look at factories around the world that are sustainable, or ethically certified, it’s still only 2% of the world’s fashion factories, which is quite astounding.”

While stating that many brands still rank very poorly in terms of sustainability indices, she concurred that there are a confusing amount of certification schemes, collaborative initiatives, campaigns and rankings that companies use sustainable fabrics from. To improve their efforts in the sustainable arena, she recommended Common Objective as a good source of information.

“There is a lot of help out there to enable companies to be more sustainable in the future,” she commented.

Talking about the high street, Julia said that it is well on its way to improving, but that it is still a long way from being as sustainable as it could be. She explained that several brands had signed up to the International Sustainability Unit and had vowed to source all of their fabrics from sustainable sources by 2025.

She highlighted M&S as a brand making headway, as it already sources 100% of its cotton from sustainable sources, and also, the huge steps made by Asda, spotlighting that “a lot of bigger businesses are doing amazing things in developing a sustainable plan and reducing their effect on the environment.”

As for smaller businesses without the same resources, she explained that Common Objectives have a suite of tools for improving sustainability – to include a sustainability road map that identifies a company’s long and short-term goals, and how to put everything into practice, advising companies how to make it happen.

“So much of what we’re doing is talking sustainability, but it’s the action that we take collectively that will really start to make a difference. It’s about pre-empting what the end customer is expecting.”

Julia continued: “We know that customers are changing their beliefs and their mindset, but, in fact, they are really relying on us to put the choices in front of them so that they can make those sustainable choices. It’s almost too much of an effort for the customer to search for it. We have to put it out there for them and make it really clear.”

Highlighting the Fashion Revolutionary Transparency Index, she explained that it showed that although over half of the companies that took part in the survey had made commitments, fewer of them had taken significant action, suggesting that it was a good resource to look at, to see what fashion brands are doing.

Julia also showed a video – Fair Trade: The First Step – created by Patagonia, to show the route the company had gone to become one of the world’s leading sustainable brands.

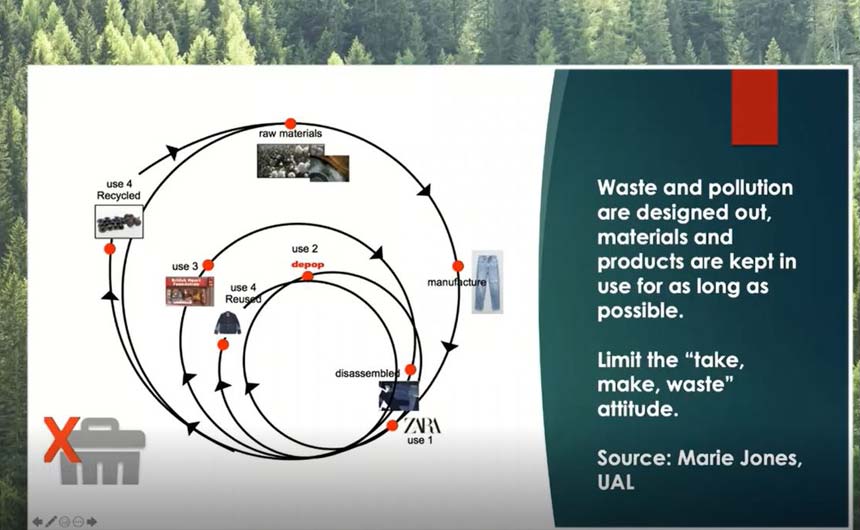

“They have been leading the charge to getting us from a linear economy to a recycling economy which is where we are at the moment,” she continued. “But it’s difficult to achieve, and means making a lot of difficult decisions along the way. However, essentially, we need to keep products in circulation for as long as possible, and at the end of their life, to find a way to break them down. It’s where the process is suffering, because there aren’t enough businesses out there that are breaking down fabrics into fibre form, so that they can be re-used or re-generated.”

As for indirect carbon emissions, Julia said that the decisions we make impact this hugely.

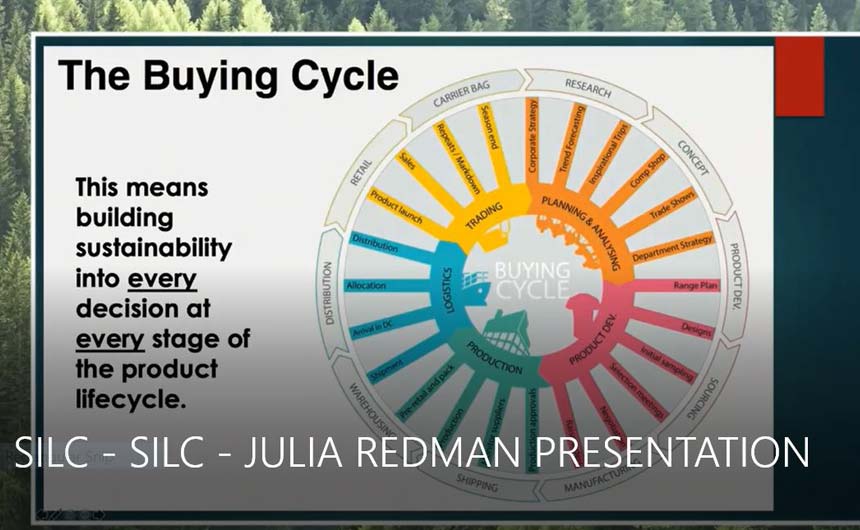

“At every stage of the process of buying something, there is a decision to be made about how sustainable we are or are not. But offsetting emissions is not necessarily the right answer. To prevent the emissions in the first place would be the best answer. But as an industry, we aren’t in that place yet, although there are other processes we can put in place to offset some of the emissions we are creating.

“All of this ties back to sustainable development goals when we are building product ranges, looking at responsible consumption and production. However, this has implications for many of the other goals, and that’s the driving force behind the decision making process that we’re going through.”

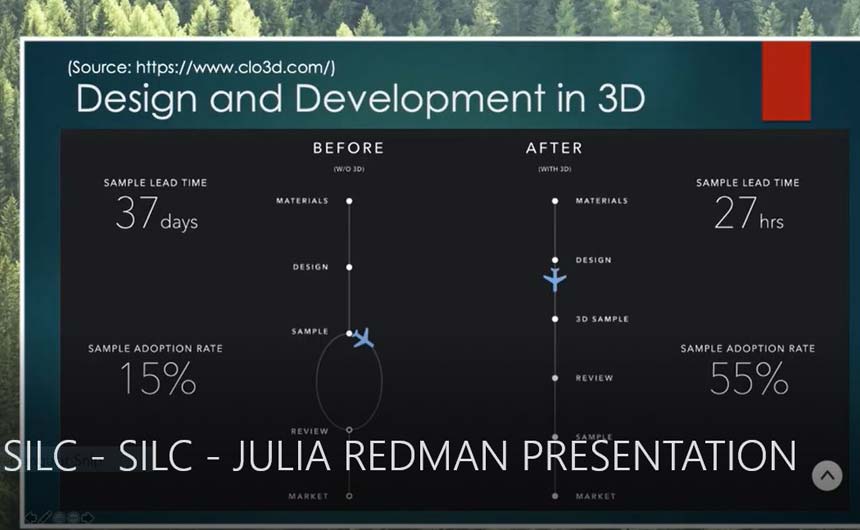

She continued: “We can do things like design and development in 3D which would reduce our sampling, reduce lead times, reduce waste, reduce costs, and over time, reduce waste, with less landfill.

“It would also reduce transportation and travel, and improve sample adoption, with a reduction in time to produce a sample. It will revolutionise the fashion industry.”

Julia said that the next step in the process is working with partners who are embracing the use of sustainable recycled fabric and yarn sources. In relation to transport and water, choosing sources that are vertical, where as many processes in the production of a product happen under one roof so that more carbon is not being emitted as result of transport between sites.

“It’s also about choosing manufacturers with water facilities on site, such as rain water harvesting and who are actively investing in the technology to reduce water usage and pollution,” Julia highlighted.

She added that use of renewable energy is another huge factor. “Many factories are now putting solar panels on their roofs and either using wind or hydro power, so again that’s a really big step that requires investment but makes a big difference to the amount of emissions.

“We have to recycle, re-use and repurpose anything we can from the production chain. Recycling paper and card into swing tickets; recycling plastic to polyester and nylon; breaking down fabric which can be used to make bags for distribution in the local area; reducing the need for single use plastic, and recycling food waste to distribute to local farmers for animal feed.

“There’s something we can do with all of this waste. It just means we have to change the way we are doing things, and there are some really interesting things going on behind the scenes. A good example is a brand called Tala where seeds are embedded in the swing tickets enabling people to take it off the garment and plant it.”

As Julia pointed out, choosing the right factory is crucial.

“We are on a mission to get as many of factories as possible onto Sedex, a platform that enables companies to share factory audits. When retailers and suppliers are looking for a new supplier that’s one of the places they’ll look. For the supplier, the benefits of being on Sedex is that they could potentially see an uptake of European customers, critically important from the perspective of the number of suppliers in Western Europe and Asia. So, whether as a supplier or a brand or a retailer, there are a huge number of steps that go into the planning and build up.”

Concluding, Julia emphasised that in order to be sustainable, we are going to have to make sustainable decisions at as many stages of the process as possible. “It will be critically important to the way fashion develops in the future and reduces its impact on the environment.”

On an encouraging note, she ended with an award winning carbon neutral factory, Mihila in Sri Lanka, the world’s first custom built green apparel factory in the world.

“I first visited it eight or nine years ago, and it completely changed my outlook,” she revealed. “I hope it gives you a few ideas to take to your factories to talk about.”